Superior Oilfield Rentals Texas: guide to services

Wiki Article

A Comprehensive Overview to the Numerous Kinds Of Oil Field Equipment and Pipeline Equipment Available

The oil and gas industry relies greatly on specific equipment for reliable extraction and transport. Numerous types of equipment, from piercing rigs to storage space containers, play important roles in this intricate process. Each tool offers distinct features that contribute to overall functional success. Recognizing these parts is vital for any person associated with the market. As the sector progresses, so too do the innovations that support it. What improvements are on the perspective?

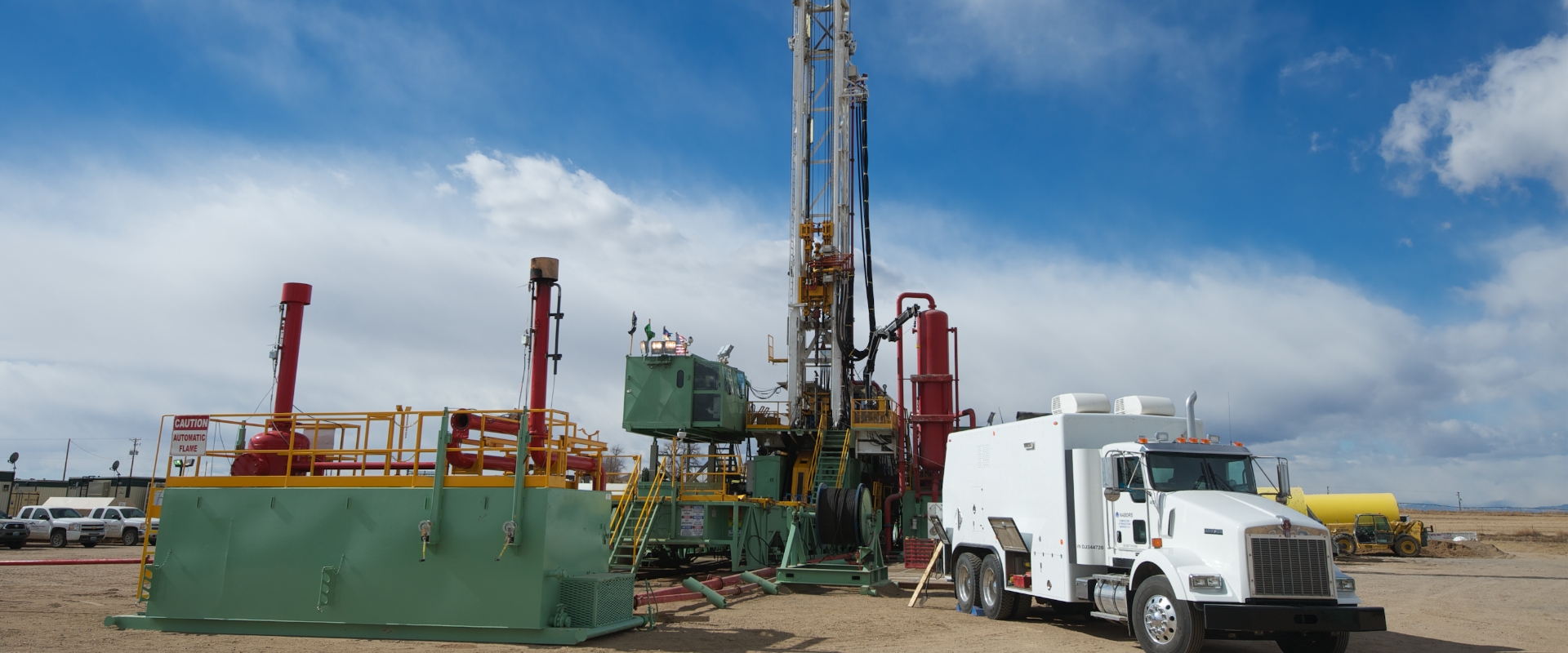

Drilling Rigs: The Foundation of Oil Expedition

Drilling rigs serve as the vital equipment in the domain of oil exploration, enabling companies to access hydrocarbon books buried deep below the Planet's surface. These rigs can be found in different kinds, including land rigs, offshore rigs, and mobile devices, each created to run in certain environments. Outfitted with advanced innovation, piercing rigs can permeate geological developments with precision, making certain reliable resource removal. The architectural integrity and functional capacities of these rigs are vital, as they have to stand up to extreme problems and significant stress. Moreover, the selection of an exploration gear influences the general job cost and timeline, making it a vital consideration for oil companies looking for to optimize their exploration initiatives and take full advantage of productivity in their operations.Pumps: Vital for Fluid Motion

In the oil removal procedure, the duty of pumps is significant, facilitating the activity of liquids throughout different stages of manufacturing. Pumps are vital for delivering unrefined oil, water, and other fluids from below ground tanks to the surface area and after that with pipes to refineries. They come in various types, including centrifugal, positive variation, and completely submersible pumps, each serving particular objectives based on the fluid qualities and functional needs. Centrifugal pumps are commonly made use of for their efficiency in high-flow applications, while favorable displacement pumps master taking care of thick fluids. The option of pump effects overall performance, operational safety, and upkeep expenses. Correct choice and upkeep of pumps are essential for maximizing manufacturing and reducing downtime in oil field procedures.Shutoffs: Managing Circulation and Pressure

Shutoffs play a vital function in taking care of the circulation and stress of liquids within oil fields and pipelines. Different sorts of shutoffs serve distinct applications, each developed to satisfy certain functions fundamental for efficient procedure - Superior Rentals reviews. Comprehending the characteristics and usages of these shutoffs is essential for enhancing system efficiency and security

Kinds of Valves

Necessary parts in oil field procedures, shutoffs play a critical duty in regulating the circulation and stress of fluids within pipes and tools. Different sorts of valves are utilized to meet the diverse needs of oil and gas manufacturing. Typical types consist of gate shutoffs, which give a straight-line flow and marginal pressure decrease; world valves, known for their throttling capacities; and round shutoffs, recognized for their quick on/off control. Furthermore, check shutoffs prevent heartburn, while butterfly valves offer a light-weight remedy for managing flow. Each valve kind is developed with specific products and arrangements to withstand the rough conditions often found in oil areas, making certain dependability and effectiveness in operations. Recognizing these kinds is crucial for reliable system monitoring.Valve Applications and Functions

While various kinds of valves offer distinct functions, their key applications rotate around managing flow and pressure within oil and gas systems. Valves such as gateway, globe, and sphere valves manage fluid motion, guaranteeing peak efficiency and security. Entrance valves are generally utilized for on/off control, offering minimal flow resistance. Globe valves, on the various other hand, offer specific flow regulation, making them ideal for strangling applications. Round shutoffs are favored for their quick procedure and limited sealing capabilities. Furthermore, stress safety valve are essential for protecting you can find out more against system overpressure, securing equipment honesty. Overall, the appropriate choice and application of valves boost operational effectiveness, making sure the reliable transport of oil and gas with pipelines and handling centers.Compressors: Enhancing Gas Transport

Compressors play a critical duty in the reliable transportation of natural gas, making sure that it moves smoothly with pipes over lengthy distances. These devices boost the pressure of gas, enabling it to conquer rubbing and altitude modifications within the pipeline system. Furthermore, compressors promote the harmonizing of supply and demand, accommodating fluctuations in intake and production prices. Various kinds of compressors are employed in the industry, consisting of centrifugal, reciprocating, and rotary screw compressors, each offering distinctive benefits based on the operational requirements. Routine upkeep of these compressors is vital to optimize efficiency and lessen downtime, eventually adding to a reputable gas transportation network. Their important feature underscores the relevance of compressors in the general oil and gas facilities.Storage Tanks: Safe and Reliable Liquid Administration

Effective transport of all-natural gas relies upon numerous support group, one of which is the appropriate monitoring of storage space containers. These tanks play a crucial role in safely including liquids, making certain that operational effectiveness is kept while lessening environmental dangers. Built from sturdy products, they are designed to stand up to high stress and harsh elements. Appropriately sized and strategically situated, storage containers facilitate the smooth flow of gas and various other liquids, protecting against bottlenecks in supply chains. Normal maintenance and monitoring are important to discover leaks or architectural sewer relining near me problems, advertising safety and security and conformity with regulatory standards. Inevitably, the reliable administration of storage space containers is important for the overall integrity and dependability of the oil and gas market's fluid handling systems.

Pipeline Systems: Framework for Transport

Pipeline systems serve as the backbone of the oil and gas sector, promoting the efficient transport of hydrocarbons over huge distances. These systems are composed of different parts, consisting of pipes, valves, pumps, and compressors, all diligently made to ensure smooth flow. The products used in pipeline building, commonly steel or high-density polyethylene, are selected for durability and resistance to rust. Pipeline networks can span throughout land and water, connecting production sites to refineries and circulation facilities. Furthermore, progressed technology makes it possible for real-time surveillance of flow rates and stress degrees, improving functional performance. The tactical placement of these pipes reduces ecological effect while making the most of resource availability, thus playing a crucial duty in meeting power needs globally.Security Equipment: Ensuring Worker and Environmental Management

The procedure of pipeline systems, while essential for energy transportation, additionally provides substantial security obstacles for employees and the environment. Safety and security equipment plays a significant function in alleviating these risks. Individual protective equipment (PPE) such as helmets, gloves, and non-slip shoes safeguards employees from physical risks. Additionally, gas detection systems keep an eye on for leakages, guaranteeing that dangerous materials do not position a danger to employees or the surrounding environment. Emergency closure systems are crucial for swiftly stopping operations during a crisis, avoiding prospective catastrophes. Spill containment products, including absorbents and obstacles, are essential for minimizing environmental influence. Overall, purchasing all-encompassing safety and security tools is vital for preserving operational integrity and securing both workers and the setting in the oil and gas market.

Frequently Asked Questions

Exactly how Do I Pick the Right Oil Field Equipment for My Project?

Picking the ideal oil area tools includes reviewing project specifications, budget plan restrictions, and functional requirements. Take into consideration factors such as equipment reliability, compatibility with existing systems, and the distributor's credibility to guarantee peak efficiency and security.What Are the Maintenance Requirements for Oil Field Equipment?

Upkeep needs for oil area equipment include routine inspections, lubrication, and prompt repair work. Operators must likewise follow maker standards, screen efficiency metrics, and warranty compliance with safety laws to improve durability and performance.

Exactly How Can I Guarantee Compliance With Environmental Rules?

To guarantee compliance with environmental policies, companies have to carry out normal audits, apply finest methods, purchase training, preserve proper documents, and stay upgraded on regulation (Superior Oilfield Rentals oilfield). Partnership with environmental companies can likewise improve adherence to policiesWhat Is the Typical Lifespan of Pipeline Equipment?

The average lifespan of pipeline devices usually varies from 20 to half a century, depending on elements such as material quality, environmental conditions, and upkeep methods. Normal inspections can considerably influence longevity and functional efficiency.Just how Do I Securely Deliver Oil Field Equipment to Remote Locations?

Delivering oil area tools to remote locations requires cautious planning, including path assessment, securing licenses, making use of proper lorries, and ensuring safety and security protocols are complied Source with. Proper training and communication among staffs are necessary for effective transport.Report this wiki page